Trainer Sinumerik (Certified by Siemens AG)

Quick Search:

808D Training

828D/840D Training

Certificate Check

Certified Trainer

CNC Consulting

CNC Programming

CNC Training

Commissioning

Consulting

Cycles

Data Security

Downloads

Ebooks (CNC)

Encryption

External Project Support

Extranet Solutions

Freelancer

Interim Management

Internet Solutions

Intranet Solutions

IT Consulting

IT Training

Lecturer

Manufacturer Cycles

OEM Cycles

Programming Services (CNC)

Project Management

Prozess Commissioning

Quality Assurance

References

Sinumerik Solutions

Sinumerik Training

Trainer

Training

User Cycles

Workshops (CNC)

Consulting

CNC

External Project Support

Workshops

Sinumerik

Commissioning

Project Management

OEM

Trainer

Intranet

Cycles

Ebooks

Consulting

Downloads

Quality

Programming

Trainer Sinumerik

Emphasis: Siemens! Here you get useful training, workshops and ready-to-use knowledge for Siemens Controller Sinumerik 828D / 840D based on your particular situation.

Operating and Programming Siemens Controls

(powerline, solution line, operate)

Sinumerik 808D, 828D and 840D sl Operate

Sinumerik 808D, 828D and 840D sl Operate Also former controls: 840C, 810D, 840D pl etc.

Also former controls: 840C, 810D, 840D pl etc. Job shop programming with ShopTurn and ShopMill

Job shop programming with ShopTurn and ShopMill G-code programming, standard cycles turning + milling

G-code programming, standard cycles turning + milling Multitasking, multi-channel machining (programSYNC)

Multitasking, multi-channel machining (programSYNC) Asynchronous subprograms (ASUP), synchronized actions

Asynchronous subprograms (ASUP), synchronized actions High level language programming, user cycles + OEM cycles

High level language programming, user cycles + OEM cycles Expanding the user interface (Run MyScreens, EasyScreen, Easy XML)

Expanding the user interface (Run MyScreens, EasyScreen, Easy XML) On site in Germany and abroad (German, English or using interpreter services)

On site in Germany and abroad (German, English or using interpreter services)

Workshops + Customer Training

Turning, milling, drilling, grinding, sheet metal cutting

Turning, milling, drilling, grinding, sheet metal cutting 2D, 2,5D, 3+2 and 5-axis simultaneous

2D, 2,5D, 3+2 and 5-axis simultaneous Special machines (also automotive), multitasking, multichannel machining (programSYNC)

Special machines (also automotive), multitasking, multichannel machining (programSYNC) Turning: 3+2 (swiveling), 5-axis simultaneous, B-axis, counter spindle, Y-axis, driven tools, measuring

Turning: 3+2 (swiveling), 5-axis simultaneous, B-axis, counter spindle, Y-axis, driven tools, measuring Milling: Swiveling (3+2), 5-axis simultaneous, process measuring

Milling: Swiveling (3+2), 5-axis simultaneous, process measuring Different kinematic types: Head kinematic, table kinematic, mixed kinematic

Different kinematic types: Head kinematic, table kinematic, mixed kinematic Work preparation, setting CNC machines

Work preparation, setting CNC machines Process optimisation

Process optimisation Customer specific issues

Customer specific issues For machine manufacturers, machine tool distributors and industry customers all over the world (also Asia)

For machine manufacturers, machine tool distributors and industry customers all over the world (also Asia)

Mobile Classroom + Certified Trainer

Certified Siemens CNC trainer since 2011 (Karsten Schneider)

Certified Siemens CNC trainer since 2011 (Karsten Schneider) Experiences with Sinumerik machine tools since 2001

Experiences with Sinumerik machine tools since 2001 Experiences with CNC machine tools since 1996

Experiences with CNC machine tools since 1996 Experiences with conventional machine tools since 1992

Experiences with conventional machine tools since 1992 Mobile classroom for in-house trainings on site

Mobile classroom for in-house trainings on site 6 laptops for participants + projector and portable projection screen

6 laptops for participants + projector and portable projection screen Current simulation software

Current simulation software Useful training documentations

Useful training documentations

Special Service: Training for Sinumerik 808D - lecturer / trainer or in-house classes in a mobile classroom or direct on your machine ...

Read more »

In the following, you will find a choice of standard courses regarding Siemens controllers:

Basic Class CNC Turning, Operating and Programming Sinumerik 828D/840D (G-Code + ShopTurn)

Target of this training is to enable the participants to create CNC programs for turning tasks using Sinumerik controller 828D resp. 840D with ShopTurn (graphical programming environment) and programGUIDE (g-code programming) and learn all the functions for Operators.

- Repetition of basics regarding CNC machine tools

- Introduction in operating and programming of Sinumerik controller

- Measure work piece, measure tool

- Working with tool management

- Handling CNC programs and other files

- Create programs for turning, milling and drilling tasks

- C-Axis, Y-Axis and driven tools

- Standard cycles and position patterns

- Using the contour editor for creating turning contours and milling contours

- Freely definable contour descriptions for blanks

- Using work offsets and programmable manipulations of the coordinate system

- Subprograms

- Loops, jumps, repetitions and elements of Sinumerik high level language

- Using parameter and variables

- Face transformation, cylinder jacket transformation

Basic Class CNC Milling, Operating and Programming Sinumerik 828D/840D (G-Code + ShopMill)

Target of this training is to enable the participants to create CNC programs for milling tasks using Sinumerik controller 828D resp. 840D with ShopMill (graphical programming environment) and programGUIDE (G-code programming) and learn all the functions for Operators.

- Repetition of basics regarding CNC machine tools

- Introduction in operating and programming of Sinumerik controller

- Measure work piece, measure tool

- Working with tool management

- Handling CNC programs and other files

- Create programs for milling and drilling tasks

- Working with an angel head

- Standard cycles and position patterns

- Using the contour editor for creating milling contours

- Using work offsets and programmable manipulations of the coordinate system

- Subprograms

- Loops, jumps, repetitions and elements of Sinumerik high level language

- Using parameter and variables

Compact Course CNC Turning + CNC Milling with Siemens Sinumerik 828D/840D

Target of this training is to enable the participants to create CNC programs for turning and milling tasks using Sinumerik controller 828D resp. 840D with ShopTurn or ShopMill (graphical programming environment) and programGUIDE (g-code programming) and learn all the functions for Operators.

- Introduction in operating and programming of Sinumerik controllers

- Measure work piece, measure tool

- Working with tool management

- Handling CNC programs and other files

- Create programs for turning tasks (G-code + ShopTurn)

- Introduction in programming C-axis and Y-axis

- Create programs for drilling and milling tasks (G-Code + ShopMill)

- Standard cycles and position patterns

- Using the contour editor for creating turning resp. milling contours

- Using work offsets and programmable manipulations of the coordinate system

- Subprograms

- Loops, jumps, repetitions and elements of Sinumerik high level language

- Using parameter and variables

Crash Course CNC Turning with Sinumerik 828D/840D

Target of this training is to enable the participants to create CNC programs for turning tasks using Sinumerik controller 828D resp. 840D with ShopTurn (graphical programming environment) and programGUIDE (g-code programming) and learn all the functions for Operators in a minimum of time.

- Introduction in operating and programming of Sinumerik controller

- Measure work piece, measure tool

- Working with tool management

- Handling CNC programs and other files

- Create programs for turning and simple milling or drilling tasks

- Standard cycles and position patterns

- Loops, jumps, repetitions

- Using the contour editor

- Using work offsets and programmable manipulations of the coordinate system

Advanced Training Course CNC Turning, working on Front Face and Sheath with Siemens Sinumerik 828D/840D

Target of this training is to enable the participants to create CNC programs for turning tasks on front face or peripheral surface with driven tools using Sinumerik controller 828D/840D with ShopTurn (graphical programming environment) and programGUIDE (g-code programming) and learn all the functions for Operators.

- Introduction in using driven tools

- Working with tool management

- Handling CNC programs and other files

- C-axis, Y-axis and driven tools

- Create programs for milling and drilling tasks

- Standard cycles and position patterns

- Using the contour editor

- Using work offsets and programmable manipulations of the coordinate system

- Loops, jumps, repetitions and elements of high level language

- Using parameter and variables

- Face transformation, cylinder jacket transformation

Advanced Training Course CNC Milling, Swiveling (3+2) with Sinumerik 840D

Target of this training is to enable the participants to create CNC programs for milling tasks on oblique surfaces with any orientation in space on a 3+2 axis milling machine using Cycle800.

- Introduction in cycle800, working plane transformation

- Repetition frames and programmable manipulations of the coordinate system

- Tilting tool + swiveling working plane

- Swivel function in JOG mode

- Cycle800 in G-code and in ShopMill

- Programming exercises: Drilling and milling tasks on oblique surfaces

Re-Certification from Siemens AG "Certified Siemens CNC Trainer" (since 2011)

Re-Certification from Siemens AG "Certified Siemens CNC Trainer" (since 2011)

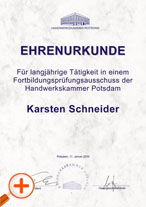

Document of the Chamber of Skilled Crafts Potsdam for long-standing Commitment in Examination Board for CNC Experts

Document of the Chamber of Skilled Crafts Potsdam for long-standing Commitment in Examination Board for CNC Experts

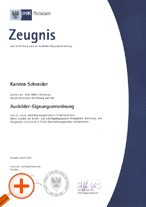

Trainer Skills Certificate of Chamber of Industry and Commerce Potsdam according to the German AEVO

Trainer Skills Certificate of Chamber of Industry and Commerce Potsdam according to the German AEVO

Contact Data

Telephone:+49 3386 286029

Telephone:+49 3386 286029

Mobile:+49 173 9995782

Mobile:+49 173 9995782

Fax:+49 3386 210415

Fax:+49 3386 210415

Email:mail@karstenschneider.de

more »

Email:mail@karstenschneider.de

more »